Have you avoided dabbling in cannabis concentrates because it seems like there’s just too much to learn? Don’t fear! We’ve got your back, and remember, everyone else started from the beginning at some point too.

Let’s start with the most important thing to understand, when we use the term concentrates, we are referring to high-purity oils extracted from cannabis using any one of a variety of different processes. It’s not wrong to refer to any type of concentrate as “oil” regardless of how oily it actually looks.

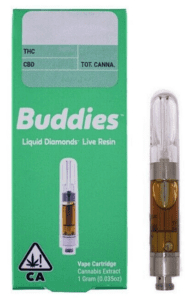

The primary factors that make one concentrate type different from another are the quality of the source material, the degree to which it’s refined, and how it’s immediately handled post-extraction. Once you know a little bit about these things, it’s easier to pick out clues on the label that will tell you something about the product you’re considering consuming.

It’s important to note that there’s no universally accepted convention for naming concentrates. What one company calls Honey Crystal, another might simply call BHO, even if the process and end result are more or less identical. In an attempt to stand out in a sea of competition, or to communicate one small tweak in a common process, brands will invent unique names to market their products. While we appreciate the nuances that make each brand’s product their own great thing, it assumes an understanding of how concentrates are made, which most consumers just don’t have. So let’s dive in and empower you to make an informed decision about your next concentrate purchase.

AN OVERVIEW OF EXTRACTION METHODS

All cannabis is covered in trichomes, which contain oil and inside of that oil is all of the “good stuff” like cannabinoids (THC, CBD, etc) and terpenes. In making concentrates, these oils are separated from the plant material to varying degrees, the unneeded parts discarded, and only the most potent and desirable parts reserved from consumption. Cannabis extraction processes can be done in a number of ways. For us, it’s easiest to think about these ways by dividing them into 5 groups:

Hydrocarbon Extraction

Hydrocarbon Extraction

This method uses solvents like butane, propane, or hexane to separate cannabinoid containing oils from their plant material inside of a big expensive piece of professional industrial equipment. Then, through an extensive purging process, those solvents are removed and only the extracted oil is reserved for consumption. This is probably the most common extraction method currently used in today’s market.

Back in the days of the black market, hydrocarbon extracts didn’t have the best reputation. There were a lot of people using unsafe DIY set-ups with a high risk of injury or fire for the producer. Additionally, the equipment didn’t guarantee a thorough purging of those solvents, so the user was at risk of consuming them in the finished concentrate. Today, safety is no longer a concern now that professional extractionists have access to industrial equipment and everything that is legally sold, must first be tested at a lab.

How to consume: Primarily dabs, sometimes cartridges.

Associated terms: wax, shatter, crumble, budder, butane hash oil (BHO).

CO2 Extraction

This method also uses an industrial machine where pressure is the main component separating the plant material from the oils. The interesting thing about CO2 extraction is that the separation happens in distinct stages defined by pauses and switching off the machinery’s receptacles. Terpenes separate early on in the process, followed by some less-desirable compounds, and then finally cannabinoids like THC and CBD. The ability to individually pull out each of these, allows producers to compose the final product from only the portions they want to keep.

How to consume: Primarily cartridges, sometimes dabs.

Associated terms: oil, Extra Virgin Flower Oil (EVFO), syrup, honey.

Manual Extraction

Manual Extraction

There are a few different techniques that fit into this category all with the common idea that physical manipulation is the driver that separates the oils from the plant material. The three most common methods are sifting, ice water, and low heat plus pressure.

Dry Sift Method: involves starting with the plant material which is then passed through a series of gradually finer screens until only the dusty looking kief remains. Most producers compress the kief into several small disk shapes making it easier to handle.

Ice Water Method: is done by taking the plant material and mixing it in a vat of ice and water. The cold temperature makes the trichomes brittle and the agitation causes them to easily separate. The water and excess plant material is then discarded, and the remaining hash is shaped into bricks or disks to dry out.

How to consume: Sprinkle over top of flower before smoking. (This method leaves more residual plant material than other methods, making it an unpleasantly harsh and messy dab).

Associated terms: Dry-Sift Hash, Bubble Hash, Kief

Heat & Pressure Method: involves pressing the plant material (leaves, flowers, or even sometimes hash) between two large heated plates. The low-heat makes the oil become more viscous while the force of the pressure squeezes it out.

What’s Live Resin?

Typically, dried, cured, consumable cannabis is used in heat/pressure extraction. However, “live” implies the cannabis has been cut and frozen at harvest time until used for extraction. This freshness guarantees a certain level of quality and preserves the most variety of possible compounds in the finished product.

How to consume: Dabs

Associated terms: Resin, Live Resin

Alcohol Extraction

Alcohol extraction is done by soaking cannabis in high proof ethanol (alcohol) which strips the trichomes from the plant material. Then the material is removed from the cannabinoid-infused solution and heat is applied so that the alcohol evaporates off. This is one of the only techniques where decarboxylation of the cannabinoids occurs in the process, thus creating a fully activated final product. However, the heat from production also removes some of the tastier compounds found in the flower, so it’s usually not pleasant to dab.

How to consume: sublingually or orally

Associated terms: Rick Simpson Oil (RSO), Whole Plant Extract (WPE)

Distillate

Distillate first starts off with a concentrate produced from any of the above processes which is then further refined using any one of a variety of different distillation techniques that could involve pressure or alcohol. The goal is to maximize the removal of plant material until the purest cannabinoid concentration is reached. The purity often makes distillates lighter in color when compared to other concentrates.

How to consume: Dabs, cartridges.

Associated terms: Distillate

A FEW NOTES ON COLOR, FLAVOR & TEXTURE

In most instances, it’s an okay rule of thumb to assume that the pricing reflects a concentrate’s overall quality. First-rate source material is more expensive to acquire, but it absolutely results in a superior dabbing or vaping experience. On the other hand, despite popular perception, color is not a great quality-indicator. Occasionally a darker color is reflective of unwanted plant material in the finished product, but more likely it’s a nod to the color of the weed that was used to make it. You’ve all seen some delicious smelling, beautiful, purple nugs, right?

The flavor is determined both by the quality of the source material and by how the preservation of terpenes are handled during extraction. The texture is somewhat determined by the extraction method, although a wide range of textures can be achieved based on how the product is handled during the process, especially as it cools and/or rests. It’s good to think about texture and color as characteristics rather than quality indicators.

Some concentrate producers grow their own flower. Other producers partner with farmers from another company to gain their source material. In either case, at Dockside, we strive to source concentrates that are made from flower that we also stock on our shelves. The hallmark of a good concentrate is if it tastes and smells like the flower it was made from. This means the extractor was able to remove less desirable compounds while keeping all of the important tasty ones!